Forged in a Trailer, Built in a Steel Mill: The Carnegie Robotics Story

By Andersen Beck, TEQ Magazine

When John Bares founded Carnegie Robotics inside a trailer in the National Robotics Engineering Center (NREC) facility in Lawrenceville, he couldn’t have imagined it would’ve sparked the fire for the Pittsburgh tech boom. Now his company operates out of a retooled steel mill, independently producing advanced tech that defines Pittsburgh’s new premier industry.

When John Bares founded Carnegie Robotics inside a trailer in the National Robotics Engineering Center (NREC) facility in Lawrenceville, he couldn’t have imagined it would’ve sparked the fire for the Pittsburgh tech boom. Now his company operates out of a retooled steel mill, independently producing advanced tech that defines Pittsburgh’s new premier industry.

Carnegie Robotics LLC (CRL) traces its history back to the earliest days of the Pittsburgh tech revolution, stemming from when NASA and Carnegie Mellon University (CMU) came together in 1996 to create NREC, of which CMU was made custodian.

NREC was established on 40th street in Lawrenceville, which at the time could be described as a “rough and tumble” neighborhood. Despite deterrents like crime and gang activity, Lawrenceville was host to some of the best building stock the city has to offer. The dissolution of Pittsburgh’s steel industries left Lawrenceville with large vacant warehouses available for cheap, making it the perfect location to plant the new high-growth tech industry.

Getting Started

“Carnegie Robotics has relied heavily on the southwest Pennsylvania region to build this company over the past several years… Pittsburgh is a great place for entrepreneurship as well as a magnet for attracting talent,” says CRL President and CEO Bares on the company’s expansion.

One of NREC’s first directors was Bares, who at the time was a staff faculty member of CMU with a PhD in Civil Engineering. Under his direction, NREC grew exponentially. In 2010, Bares left his staff position with CMU to start CRL.

Starting out in a trailer in the NREC space, CRL began with a mission to form the commercial production end of what academic researchers were generating.

Starting out in a trailer in the NREC space, CRL began with a mission to form the commercial production end of what academic researchers were generating.

“The universities were doing an exceptional job designing and developing, but they weren’t suited to produce components, or for mid or large scale production of these materials. That’s not how the universities are set up,” explains CRL’s Chief Development Officer Mike Embrescia.

Bares set out to create a company known for its excellence in engineering, on-site component production, and having the capabilities for on-site testing and calibration. Being able to perform all of the commissioning under one roof would set CRL apart from other OEMs, and being able to test and rework products on-site with the very people who designed them would be paramount to their success.

Gaining Momentum

Four years after being founded, CRL moved into its existing facility across the street at the former Heppenstall steel factory on the corner of 45th and Hatfield street. It’s a sprawling, bright blue warehouse with a 5-acre yard space, perimetered by a 10-foot brick wall; perfect for putting their autonomous off-road driving tech to the test.

Four years after being founded, CRL moved into its existing facility across the street at the former Heppenstall steel factory on the corner of 45th and Hatfield street. It’s a sprawling, bright blue warehouse with a 5-acre yard space, perimetered by a 10-foot brick wall; perfect for putting their autonomous off-road driving tech to the test.

The yard is perhaps CRL’s greatest location asset. Engineers have the ability to test their robotic vehicles for data collection right outside the back door. If 5-acres aren’t enough, they’ll perform tests in their 400-acre Penn Hills site, which they’ve appropriated from a former U.S. Steel slag dump. Should they need an even bigger space, they’ll haul out to their licensed 1,000-acre site in Somerset County, where they can really let their machines roar.

CRL has been specializing in autonomous products since 2015, when Travis Kalanick, then-CEO of Uber, came literally knocking on their door. Kalanick wanted to buy CRL to begin work on an autonomous ride-hailing vehicle. CRL informed him the company was not for sale, however within five weeks Bares was able to strike a new deal with Kalanick. Uber would acquire some of CRL’s IP, and Bares would become founding director of Uber ATG (Advanced Technology Group). Uber’s self-driving work was born in the CRL warehouse right in Lawrenceville.

Before the San Francisco money could flood into the Pittsburgh tech scene, Bares was using a corporate credit card to buy a couple vehicle lifts, some Volvos, and some Ford Fusions. They began upfitting the cars with data-collecting sensors and sent them out all over the city. From this very project came several well-known companies such as Argo AI, Aurora AI, Locomotion, Waymo, Cruise, and Kodiak Robotics, all stemming from Uber ATG.

Bares and colleagues grew Uber ATG to host about a thousand people and around one million miles of on-road autonomy. After two years, Bares returned to CRL from Uber ATG to change gears from on-road autonomy to off-road.

Taking Off

Since 2017, CRL has grown organically, bolstering its industry partnerships with some of the world’s top global players, such as Brunswick, Boston Whaler, Caterpillar, Lockheed Martin, and Booz Allen. Most impressively, CRL has gotten to its current status without ever receiving outside investors, private equity, or venture capital; to this day they remain wholly and proudly independent.

“We’ve been profitable for 13 of the last 15 years … Our balance sheet is very strong, our revenues are very strong, and we have little to no debt. We have created a diverse growth strategy and revenue model whereby our work in defense versus our work in the commercial OEM sector are roughly on par with each other, almost fifty-fifty,” says Embrescia.

“We’ve been profitable for 13 of the last 15 years … Our balance sheet is very strong, our revenues are very strong, and we have little to no debt. We have created a diverse growth strategy and revenue model whereby our work in defense versus our work in the commercial OEM sector are roughly on par with each other, almost fifty-fifty,” says Embrescia.

While margins are higher in commercial work, there are sometimes trade-offs with IP. Clients get to buy and own IP, but CRL gets to retain certain aspects of it via working with their own pre-developed background IP.

When working on defense projects however, margins are significantly lower but you’re working with non-dilutive capital (meaning funding without having to give up equity or ownership). On these deals CRL can develop lots of technologies and IP and sometimes keep special-purpose rights, which allows them to leverage that IP into technologies to be sold commercially.

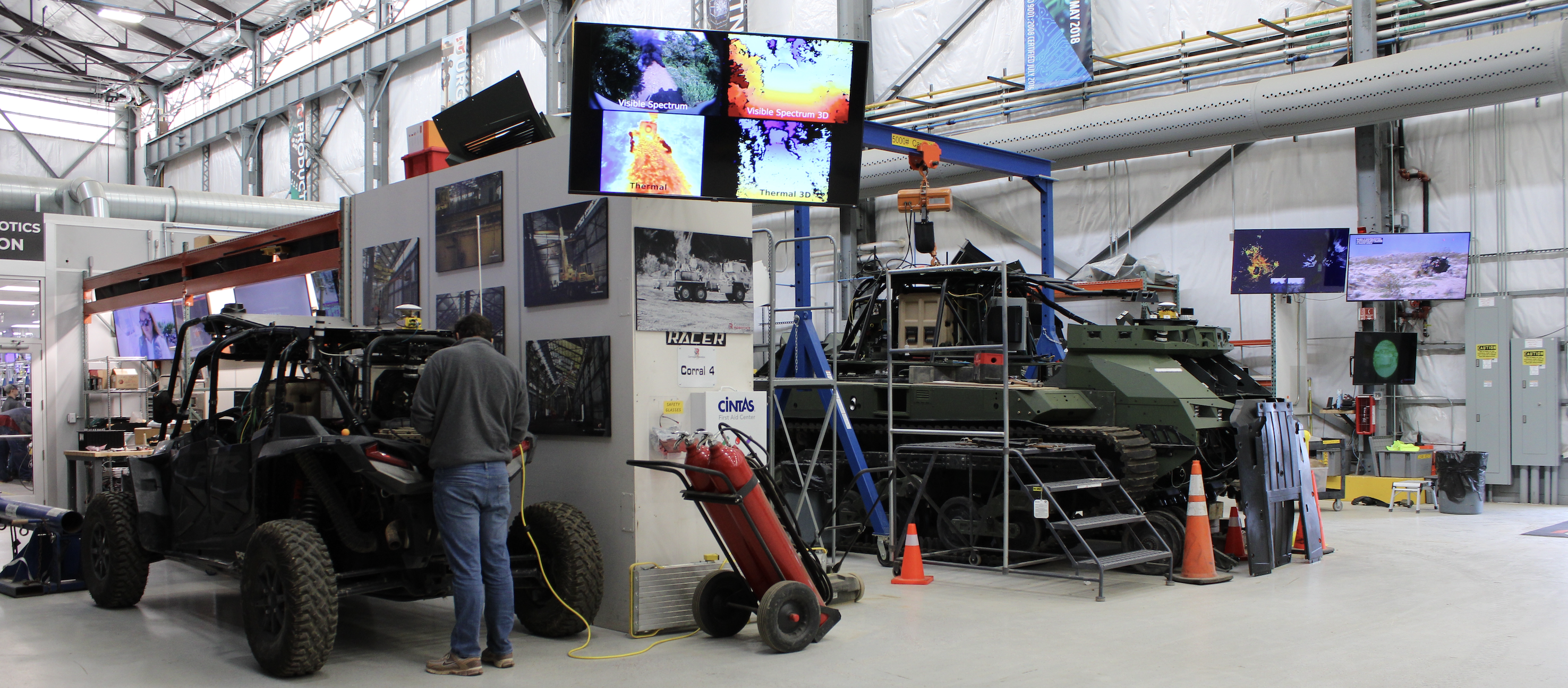

They’ve maintained steady and healthy business through their aforementioned model, keeping everything in-house. CRL can produce autonomous systems and develop their associated product under one roof thanks to their headquarters hosting both a full-service mechanical workshop as well as an ISO 9001-certified production facility, which can be interchanged to suit any number of new projects. Their state-of-the-art production faculties include a highly thorough quality department, on-site calibration, thermal testing, shake and vibe tables, accelerated life testing and more.

Leading the Way

In the past few years, CRL has been producing groundbreaking work in commercial autonomous tech, concentrating on rugged products for harsh terrains. Their work with the Brunswick corporation has seen them develop the autonomy for a self-docking Boston Whaler boat; a first of its kind, and will be available in fall 2025. Additionally, CRL was able to save Swift Navigation’s DURO system by buying the product rights, fitting it with military-grade hardware for extreme environments, and selling it as their own.

As well as their commercial victories, CRL has made perhaps even more exciting strides in the defense sector. In partnership with Booz Allen, CRL developed CardShark, a highly powerful, highly capable body-worn compute system designed to operate advanced computer functions in active war zones. Just as well, CRL was selected to participate in DARPA’s premier ground-autonomy program titled RACER (Robotic Autonomy in Complex Environments with Resiliency).

For RACER, CRL has designed, built, and upfitted over 20 autonomous Polaris RZR’s and 4 Textron Ripsaws (cab-less tracked vehicle: a tank). They’re sent out from Pittsburgh to project teams all over the country to compete in trials. The Department of Defense recognizes CRL’s work as top of their class, which has opened many doors for high level projects.

“Carnegie Robotics has relied heavily on the southwest Pennsylvania region to build this company over the past several years… Pittsburgh is a great place for entrepreneurship as well as a magnet for attracting talent,” says CRL President and CEO Bares on the company’s expansion.

Currently, CRL has been working on the DIU’s (Defense Innovation Unit) GEARS program (Ground Expeditionary Autonomous Retrofit System). They were asked to compete in this program in 2024, against two other companies. One of the companies had 10 years of experience on the program, the other had eight, CRL had nine months to perform. Their mettle was tested, but by the end of phase one, CRL was selected above another company to continue on to phase two. In phase two, CRL has been autonomizing eight, 15-ton Oshkosh PLS (Palletized Load System) trucks that supply trailers.

From its origins in NREC to its remarkable advancements in autonomization, CRL’s story is one that all budding tech firms strive to live out. Woven into the tapestry of Pittsburgh’s globally influential industry, CRL has many exciting projects on the way -- and to think it all started by thinking big in a small trailer outside an old steel mill.

Andersen Beck is an independent journalist, freelance writer and founder of bloodhoundmag.com.