Start Me Up: Four Pittsburgh Robotics Companies at the Robotics Factory

By Sheena Carroll

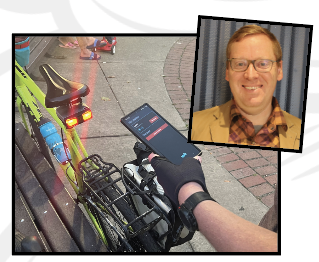

Velo AI: Copilot's Advanced AI Keeps Cyclists Safe on the Road

Founder and CEO of Velo AI, Clark Haynes is a lifelong bike commuter who worked in the advanced robotics and autonomous vehicle industries for many years. He was initially attracted to autonomous vehicles because he thought that they may be the answer to safer roads for bicyclists and pedestrians.

Founder and CEO of Velo AI, Clark Haynes is a lifelong bike commuter who worked in the advanced robotics and autonomous vehicle industries for many years. He was initially attracted to autonomous vehicles because he thought that they may be the answer to safer roads for bicyclists and pedestrians.

“But it’s been nine years since we started seriously working on autonomous vehicles, and our streets are now more dangerous than ever,” said Haynes. “Pedestrian fatalities are up 60%, while bicyclist fatalities are up 43%. The motivation behind Velo AI is to apply technology in new ways that can improve safety for all.”

Velo AI’s Copilot device is designed to improve situational awareness for all parties on the road. The small, battery-operated autonomy system sits under the seat of the bike and looks backwards, tracking vehicles and identifying their behavior and any aggression. Copilot provides visual and audio alerts so that cyclists can more safely be informed about what is happening behind them.

As a part of the Robotics Factory’s Accelerate Program, Velo AI has received assistance in everything from finance to partnerships with local manufacturers.

“During one’s career, you are typically focusing on only one or a few things,” said Haynes. “With startups, you have to focus on everything. There is no way that you can know how to do everything from the get-go. I think that is one of the major areas where the Accelerator Program has helped us – by showing us the 10% that we need to know to get 90% of the way. It’s a crash course in how to run and grow a business.”

ESTAT Actuation: "Electric Glue" Creates the World's Most Powerful Clutches, Brakes, Latches and Locks

ESTAT Actuation isn’t just a member of the Robotics Factory’s latest Scale Program cohort – they are also the Factory’s neighbor in

ESTAT Actuation isn’t just a member of the Robotics Factory’s latest Scale Program cohort – they are also the Factory’s neighbor in

Lawrenceville’s Robotics Row.

“Our office is located just down the street, but sometimes we have a need for quick prototyping,” explained Kirby Witte, ESTAT’s VP of Engineering. “This usually means going through a machine shop and dealing with 6-8 week waiting times and significant expenses. Now that the Robotics Factory is here, we have access to a lot of equipment and expertise to push prototypes through faster and to easier flesh out ideas.”

Witte previously worked in surgical robotics. While studying and building exoskeletons at CMU, she met ESTAT’s future Founder and CEO, Stuart Diller.

“We were in the same lab working together…I was using [Diller’s] clutches on my exoskeletons. He was developing electric glue, which he uses to create the world’s most powerful and compact clutches. We enjoyed working together and it was very clear the power that this technology had,” said Witte.

“If you ever want to establish a connection and break it in a controllable way, that’s a great way to use our products. Clutches, brakes, locks, and latches are all great applications of our electric glue.”

ESTAT serves several industries, ranging from consumer electronics to aerospace engineering. They are currently developing their own catalog; this will save customers from spending a fortune on R&D projects by allowing them to buy components “right off the shelf.” They also offer custom product design with a turnaround as short as 8-12 weeks.

The Robotics Factory has been pivotal in their upscaling; in just the past few months of joining the program, ESTAT has developed parts for new clutches, received advice on performing quality control checks, and given access to 3D scanners for rapid, accurate measurements.

“Startups have a small number of employees, and the amount of expertise is limited. Having access to people who have done this before is incredibly helpful.”

Cell X Technologies: Automated Solutions to Shorten Regenerative Medicine Process Times

Cell X Technologies, a spin-off of tech developed by Cleveland Clinic and Parker Hannifin, is focused on regenerative medicine as its end user market. The company has developed an automated solution to enable developers of these treatments to significantly shorten their process times.

Cell X Technologies, a spin-off of tech developed by Cleveland Clinic and Parker Hannifin, is focused on regenerative medicine as its end user market. The company has developed an automated solution to enable developers of these treatments to significantly shorten their process times.

“Regenerative medicine is based on using human cells as a therapeutic,” Brian Handerhan, VP of Operations and Robotics, explained. “The cells are taken, engineered, and then reintroduced into the body.”

Regenerative medicine is used to treat many different things; for example, the company’s first customer is utilizing their technology with the goal to efficiently take skin cells and move them down the path to become retinal organoids to cure certain forms of childhood blindness. Similar therapeutics may one day be used to cure diabetes, heart disease and other illnesses currently considered to be incurable. Handerhan explained that many researchers are already actively working on these therapeutics.

“The downside is that none of these treatments have received FDA approval,” he said. “One of the reasons is because working with cells as both a raw material and an end product is almost completely done manually. Researchers don’t have a good scale-up solution to treat more patients. The number of patients who could be treated would be very low, while the price would be very high.”

The company is developing a presence in Pittsburgh, with the idea that the city will become its engineering and software headquarters. Joining the Robotics Factory’s Accelerate Program has allowed them to focus on transitioning their product to the manufacturing phase.

“Robotics Factory brought us into a broader ecosystem, opening a lot of doors. We are currently recruiting in the Pittsburgh area. We also want to add to our supply and partner bases, particularly on the manufacturing side.”

Handerhan’s background has always been with Fortune 250 companies; those companies have a level of structure that a startup doesn’t.

“How do you balance the level of detail and documentation that a startup has versus what our industry requires? The programming offered at the Robotics Factory really helped us define and walk the line between the two.”

Aquatonomy: Making a Splash With a Robot Purpose- Built to Excel in the Extreme Challenges Presented Underwater

For humans and machines alike, working underwater is no easy feat! Water pressure poses a challenge for both, and salt water can negatively affect equipment. Radio communication and GPS tracking are also affected – electromagnetic waves cannot travel at the depths that many commercial divers do – and visibility is also often poor.

For humans and machines alike, working underwater is no easy feat! Water pressure poses a challenge for both, and salt water can negatively affect equipment. Radio communication and GPS tracking are also affected – electromagnetic waves cannot travel at the depths that many commercial divers do – and visibility is also often poor.

“Human divers remain the industry standard,” said Aquatonomy roboticist Taylor Pool. “But it’s difficult for them to have a notion of their location.”

Aquatonomy’s robotics provides their customers with location information, potential areas of interest and a detailed assessment of their assets.

The tech behind it was developed over the course of 15 years by Co-founder Dr. Michael Kaess. Associate Professor in the Robotics Institute at CMU and a former Research Scientist at MIT, his research in robot perception and autonomous navigation has been funded by organizations including the Office of Naval Research.

Aquatonomy provides 3D models that provide accurate measurements and opens the door to new insights about the integrity of company assets. It both helps keep humans out of harm’s way, while allowing companies to reduce their labor time.

Dr. Xiaoyu Kaess, another Co-founder, has a background in human-centered design and focuses on how the company can best craft their technology for users to maximize their value. One of the ways she has done this is by interviewing hundreds of divers and companies to learn about the environmental and financial factors that affect their work. She and Pool were so passionate about better understanding the human element that they also received their licenses in recreational diving.

“It helps me to understand underwater challenges by experiencing them myself,” explained Xiaoyu. “During field trials, we dove to the location first to gather info. And then we followed the robot to observe its work.”

A part of Robotics Factory’s Accelerate Program, Aquatonomy appreciates the opportunities that it has provided. Xiaoyu notes that the whole program was very thoughtfully designed.

“It connected us with mentors who were successful robotics entrepreneurs,” she said. “One of the key factors of our success was having these mentors and being connected to the robotics ecosystem.

“Robotics Factory helped us discover what we do best. Everyone here wholeheartedly supported our needs. The culture in Pittsburgh is about lifting each other up. We share success here.”