ARM Institute and Catalyst Connection Lead Adoption of Robotics and AI

By Todd Miller

As partners for the Robotics Adoption aspect of the U.S. Economic Development Administration’s American Rescue Plan Build Back Better Regional Challenge (BBBRC) under the New Economy Collaborative’s leadership, the Advanced Robotics for Manufacturing (ARM) Institute and Catalyst Connection are helping small- and medium-sized manufacturers (SMMs – companies that have 500 or fewer employees and generate $100 million or less in annual revenue) determine how they can benefit from integrating robotics and artificial intelligence (AI) with their operations.

As partners for the Robotics Adoption aspect of the U.S. Economic Development Administration’s American Rescue Plan Build Back Better Regional Challenge (BBBRC) under the New Economy Collaborative’s leadership, the Advanced Robotics for Manufacturing (ARM) Institute and Catalyst Connection are helping small- and medium-sized manufacturers (SMMs – companies that have 500 or fewer employees and generate $100 million or less in annual revenue) determine how they can benefit from integrating robotics and artificial intelligence (AI) with their operations.

The organizations are also helping businesses secure funding for technology implementation.

Generally, the ARM Institute performs automation assessments of businesses to determine whether robotics and AI could benefit a company’s operations and helps them to test these solutions through their Robotics Manufacturing Hub. The ARM Institute also works with the Regional Industrial Development Corporation to help several regional Innovation Accelerators expand their offerings to local manufacturers. Catalyst Connection helps to fund technology implementation to “de-risk” adoption, making it easier for SMMs to invest in robotics and AI technologies.

The ARM Institute was created seven years ago through Carnegie Mellon University (CMU) winning the bid to establish a robotics-focused Manufacturing USA Institute. The ARM Institute operates as an independent nonprofit organization that helps to strengthen manufacturing nationwide through innovations in advanced technologies such as robotics and artificial intelligence (AI) and prepares the workforce to use those technologies.

Catalyst Connection is a private not-for-profit organization that was established more than 35 years ago. It provides consulting and training services to SMMs in southwestern Pennsylvania to help them accelerate revenue growth and improve productivity.

Catalyst Connection is a private not-for-profit organization that was established more than 35 years ago. It provides consulting and training services to SMMs in southwestern Pennsylvania to help them accelerate revenue growth and improve productivity.

Organizations partnering with the ARM Institute and Catalyst Connection are Regional Industrial Development Corporation; Community College of Allegheny County; Westmoreland County Community College; Indiana University of Pennsylvania

Research Institute; Digital Foundry at Pennsylvania State University New Kensington; University of Pittsburgh; CMU; and Johnstown Area Regional Industries.

That spirit of collaboration was illustrated this past February when the ARM Institute and Catalyst Connection held a Robotic Sanding & Grinding Workshop. More than 20 manufacturers and 80 participants were in attendance, underscoring high levels of interest and engagement in automation, and the demand for that kind of technology.

Milestones Reached & Upcoming

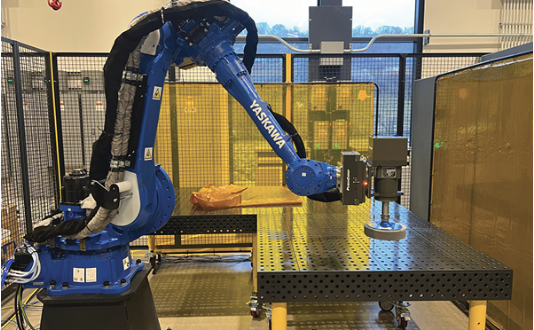

According to Livia Rice, the ARM Institute’s Senior Outreach Manager, “The ARM Institute has achieved its first two key milestones by creating a Robotics Manufacturing Hub in southwestern Pennsylvania where manufacturers can test robotics solutions before deciding whether to implement them on the production floor or in other aspects of their operations. We are so excited about being involved in this partnership because it allows us to help companies in our backyard.”

Additionally, representatives of the organization have met with 25 companies about using the Robotics Manufacturing Hub and are actively working with 10 companies to help them improve operating efficiency through robotics and AI.

Additionally, representatives of the organization have met with 25 companies about using the Robotics Manufacturing Hub and are actively working with 10 companies to help them improve operating efficiency through robotics and AI.

Catalyst Connection’s milestones to achieve over the next four years include outreach to 600 SMMs, 120 technology assessments performed, securing 60 technology adoption planning projects, and 30 implementation assistance projects, creating 150 jobs, and retaining 300 jobs.

To date, Catalyst Connection has engaged with more than 40 SMMs for technology planning projects and 20 SMMs for technology implementation projects. At this early stage, the organization’s capital assistance fund is almost fully

subscribed.

Over the next four years, the ARM Institute and Catalyst Connection will also embark on engagement campaigns with SMMs, including those in economically distressed and underserved areas. “The purpose of these interactions is to build a corporate culture that will help SMM leaders understand the benefits of adopting robotics and automation,” says Petra Mitchell, Catalyst Connection’s President and CEO.

That education process includes determining whether robotics and AI are conducive to applications related to SMMs’ product design, development and commercialization goals, as well as overcoming workforce shortages, eliminating production bottlenecks and monotonous or hazardous tasks, and increasing the visibility of data.

“We help guide SMMs through the process of considering technology solutions and implementing those solutions where they fit their business needs,” says Mitchell. “We are a trusted advisor to the companies we serve and can leverage our funding to provide no-cost or low-cost services to be an extension of their team. One of the biggest challenges faced by the SMMs we work with is a lack of time. We help them overcome that obstacle and any others that may be keeping them from achieving their strategic business goals.”

Early Adopters

In the early stages of implementation, there are numerous application stories to report. The ARM Institute worked with a local manufacturer of forgings and castings that wanted to automate its manual quality inspection process. The ARM Institute partnered with FARO and NEFF Automation to perform a proof of concept of a universal robot controlling a FARO laser scanner. The ARM Institute demonstrated the solution to the manufacturer in the Robotics Manufacturing Hub, and the manufacturer is pursuing it.

In another instance, a company needed to package heavy iron and steel parts into shipping crates. Ergonomically, it doesn’t make sense for a person to perform this job, so the ARM Institute partnered with Capsen Robotics to test the solution in the Robotics Manufacturing Hub.

The robotic and effector requirements were highly specific, and it was important to calculate the correct pick place on the parts and speed limitations of the robot to move heavy parts and prevent failure or injury. This project is near completion and is expected to conclude later this year.

There have also been a few cases in which robotics were determined to be unfeasible. In those instances, products manufactured were highly customized and low volume, making a robotics solution cost-prohibitive. In those instances, the ARM Institute has provided analyses and saved SMMs valuable time and money.

“We help guide SMMs through the process of considering technology solutions and implementing those solutions where they fit their business needs,” says Mitchell. “We are a trusted advisor to the companies we serve and can leverage our funding to provide no-cost or low-cost services to be an extension of their team. One of the biggest challenges faced by the SMMs we work with is a lack of time. We help them overcome that obstacle and any others that may be keeping them from achieving their strategic business goals.”

In another case, Catalyst Connection worked with Perpetual Enterprises a contract fabricator of metal and institutional furniture located in Coraopolis, PA, that offers a wide range of custom and standard products, including tables, storage towers, free-standing desks, workstations, open shelving and seating.

Perpetual’s custom capabilities include a variety of manual processing operations required by a given job. When the volume of a particular customer part family increased to a level that required two full-time operators to sand parts, including overtime and weekends, management knew there had to be a better way.

Additionally, completing the repetitive motion required by the manual sanding task took a large physical toll on the operators. Assigning more of their limited staff, including management, to the manual random orbital sanding task was not sustainable.

Upon hearing of the newly released Build Back Better award for southwestern Pennsylvania and Catalyst Connection’s Digital Bridge program focused on supporting manufacturers with technology adoption, Ken Hoff, President of Perpetual Enterprises, was immediately interested. “We were already engaged with Catalyst Connection on an ERP implementation project, so it was an easy call to make to explore a program that could help address our sanding bottleneck. The potential funding was a big draw as well,” Hoff recalls.

As a result of the implementation, weekend and overtime work to sand parts has been eliminated and the management team has its weekends back.

Perpetual and Catalyst Connection strengthened their relationship by recently embarking on a System Integrator Selection Assistance project that provided end-to-end support that included validating technology opportunities and their estimated impact on the company, defining manufacturing requirements, developing RFP documentation, researching suitable providers in the region and beyond, managing the RFP process to obtain qualified proposals, and supporting proposal review and the decision-making process for equipment acquisition.

Although the adoption of AI and robotics under the BBBRC initiative is in its early stages, the collaborative and individual work that the ARM Institute and Catalyst Connection have done in a short amount of time are signals for a successful future.