Pipe Dream: CMU Robot to Detect and Fix Problems in Gas Pipelines

By Byron Spice, Carnegie Mellon University

Researchers in Carnegie Mellon University's Robotics Institute are developing a modular robot that can creep inside natural gas pipelines to map where pipes are, detect decrepit or leaking pipes, and, when necessary, repair the pipe by applying a resin coating along its inner wall.

Researchers in Carnegie Mellon University's Robotics Institute are developing a modular robot that can creep inside natural gas pipelines to map where pipes are, detect decrepit or leaking pipes, and, when necessary, repair the pipe by applying a resin coating along its inner wall.

"We don't even know where all the old pipes are," said Howie Choset, the Kav?i?-Moura Professor of Computer Science, who directs the project in the Biorobotics Lab with research scientist Lu Li.

The confined spaces of pipes, largely inaccessible to people, are a natural place to deploy robots. Over the years, CMU researchers and spinout companies have developed a number of schemes and robots for inspecting sewer, gas distribution and nuclear power plant pipes. Choset, for example, headed a demonstration project that sent snake-like robots into the pipes of a mothballed nuclear plant.

The latest project, now nearing completion after three years, includes not only robotic inspection of natural gas pipes but also repair via robot. It is sponsored by the U.S. Department of Energy (DOE) through the Advanced Research Projects Agency-Energy (ARPA-E) and its Rapid Encapsulation of Pipelines Avoiding Intensive Replacement (REPAIR) program.

Natural gas in the U.S. arrives at 75 million homes and more than five million commercial customers through a network of 1.2 million miles of distribution main lines and 900,000 miles of service lines, according to the DOE. It costs up to $10 million per mile to excavate and repair these existing lines. The REPAIR program aims to use robots and smart coatings to build new pipes within leaky ones. This process — leaving the pipes in place and repairing them from the inside out — could drastically cut costs by DOE estimates.

The DOE wants repairs that will last at least 50 years, and is especially interested in inspection and repair of cast iron and bare steel pipes. Though these pipes have largely been supplanted by ones made of black steel and other materials, they still make up about 3% of the network and account for a disproportionate number of leaks and failures.

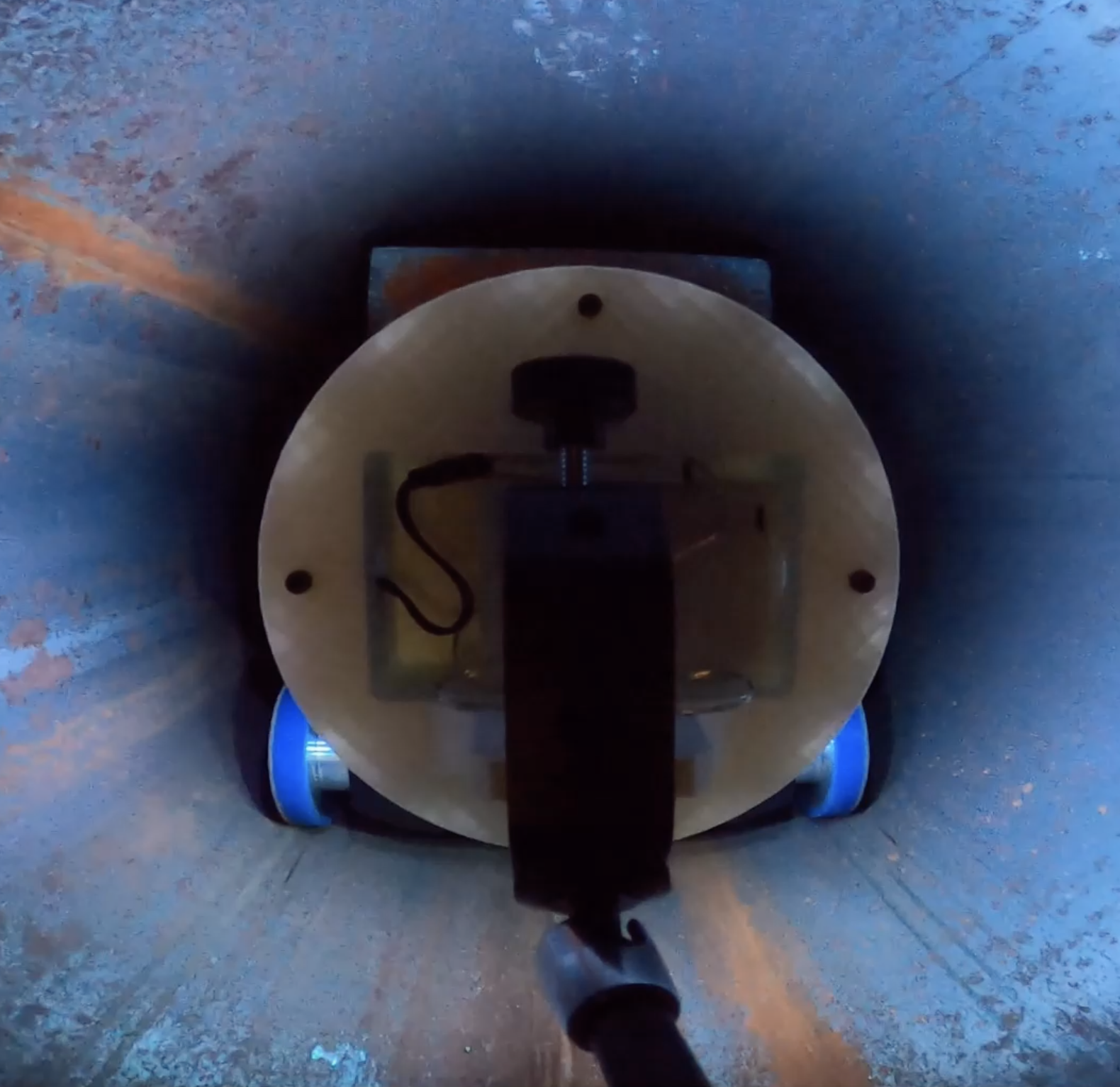

The robotic system being developed by CMU could be deployed in pipes of any material. It's also modular, so it can be configured for each job. It includes a mobility module that sits on a pair of two-inch wheels, with a third wheel atop the module. Both the pipe-repair resin and the batteries that power the robot can be quite heavy, and the three wheels supply the traction necessary for the module to pull up to 60 pounds of payload.

The robot system isn't particularly speedy, but it can inspect about nine miles of pipe in eight hours. Repair operations need to be a bit slower, Lu said, but can rehabilitate about 1.8 miles of pipe in eight hours.

"I think the resin is the real star of the show," Choset said.

Developed by the University of Illinois, the resin initially has the consistency of soft-serve ice cream, but hardens within seconds once applied to the pipe wall. The CMU researchers have developed a robot module with a spinning nozzle that applies resin as a continuous bead that spirals along the pipe wall as the robot inches along. A Colorado company is in the process of commercializing the resin.

In addition to a resin-application module, the system includes a mapping module, which features a high-resolution optical sensor. The sensor examines the color of the pipe and uses a laser system to make precise measurements of pipe defects to build three-dimensional reconstructions. Engineers on the inspection site can use augmented reality to find and map surface connectors, weld seams and identify structural defects. Artificial intelligence helps evaluate the robot-gathered data. The robots use a technique called simultaneous localization and mapping (SLAM) to produce highly detailed maps of the pipes.

The researchers have evaluated their system using a testbed built by Peoples Gas. The robotic system now has a 200-foot range, Li said, but the eventual goal is two kilometers (around 6,500 feet).

Lu said the current version of the robot is designed for 12-inch diameter pipes and a version for 6-inch pipes is in development.

"We believe we can also reduce the size to a 2-inch diameter in the near future," Lu said, but it will be an added challenge. "Smaller is harder."

For More Information

Aaron Aupperlee | 412-268-9068 | aaupperlee@cmu.edu